Clock Suspension Spring Replacement

A quick highlight of a job done right vs done wrong. A clock repair was recently brought in which had been repaired by a grandfather at some point; it worked for a while but not long. Hopefully, it’s clear from the photos below what caused the issue. A bad repair of the suspension spring involving solder and blu tac eventually failed (unsurprisingly).

Below I’d like to show some of the steps involved in repairing this part of the clock properly which involves replacing the suspension spring and absolutely no solder or blu tac.

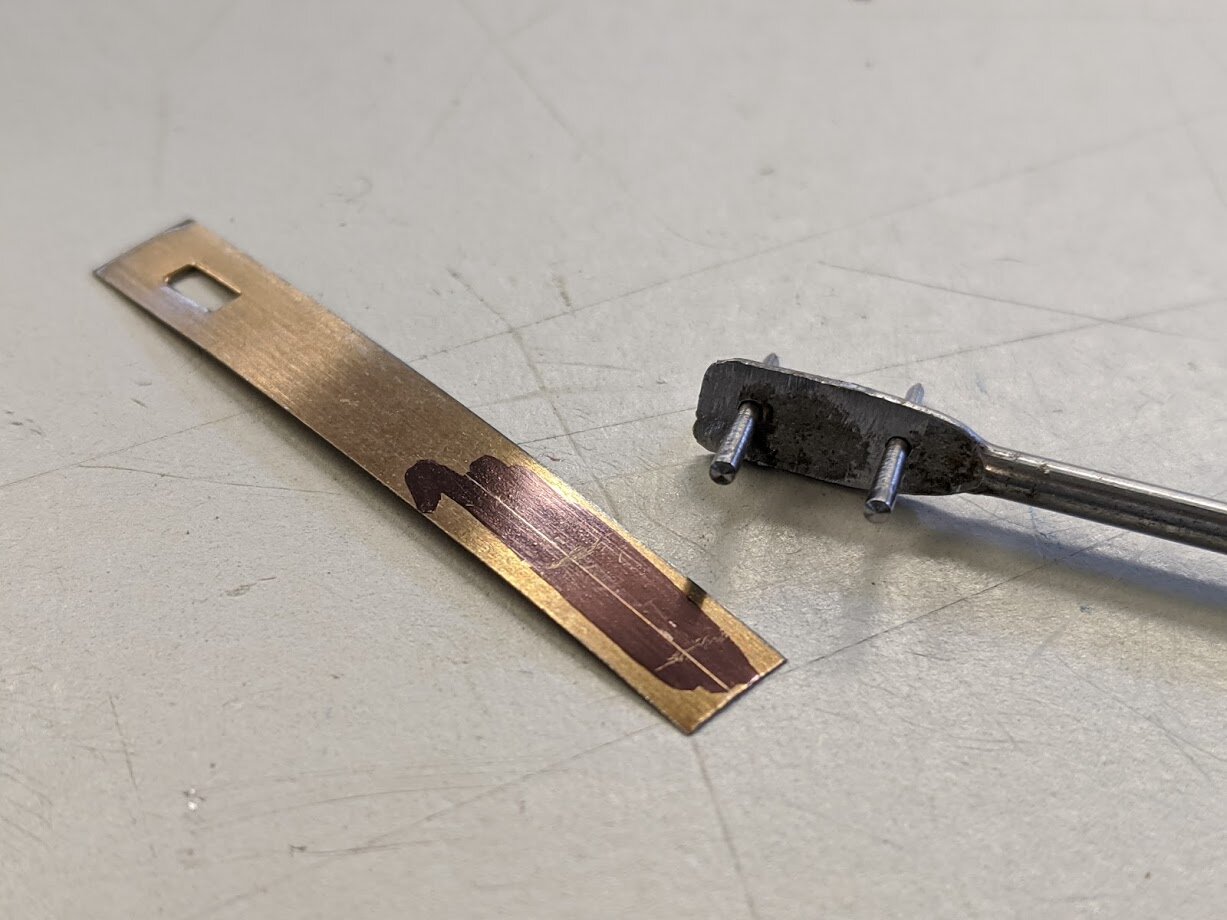

In the first step, you can see I've removed the original rivets and fitted new pins to the pendulum which have allowed me to mark out the positions of holes to be made in the replacement suspension spring. It’s very important to mark out the centre of the spring too, so everything is lined up centrally.

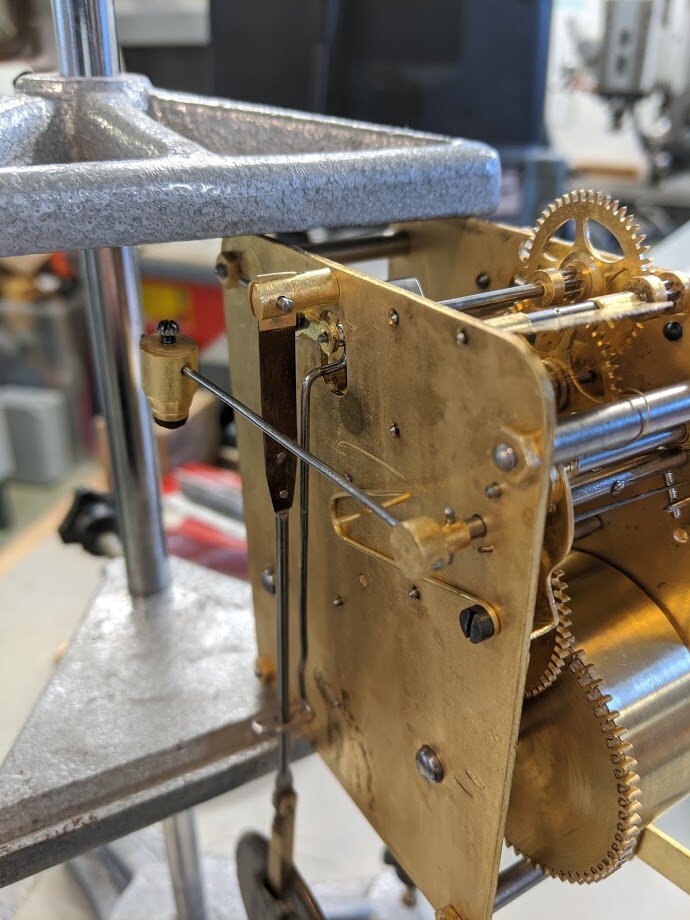

Below you can see the pendulum fitted to the suspension spring and brass shim which has been fitted around the top in order to fit the suspension spring properly into the back cock which supports it. without this, the spring would be free to wobble as it moved which would affect the action of the clock and likely cause many problems.